Lytzen ISO Class 5 (Class 100) Depyrogenation Oven

Lytzen ISO Class 5 (Class 100) Depyrogenation Oven

Contact us for price

Location:Duxford, United Kingdom

Available quantity:1

Description

This listing is for the Lytzen ISO Class 5 (Class 100) Depyrogenation Oven .

The unit is in full working condition and is ready for immediate use.

Overview

Lytzen Depyrogenation Ovens are high-performance dry heat sterilizers designed for sterilizing and depyrogenating pharmaceutical containers such as glass vials, ampoules, and bottles. These ovens maintain ISO Class 5 (Class 100) cleanroom conditions throughout the entire process cycle, even at elevated temperatures. Manufactured in Denmark, Lytzen ovens are recognized for their advanced chamber design, precision engineering, and full GMP compliance.

Key Features

ISO Class 5 at High Temperatures

ISO 14644-1 Class 5 (Class 100) Certified: Maintains Class 5 air cleanliness throughout the entire cycle.

Up to 280 °C Airflow Integrity: Delivers unidirectional HEPA-filtered airflow at temperatures up to 280 °C, enabled by Lytzen’s unique chamber construction and filter suspension system.

Continuous Clean Air Protection: HEPA filtration remains stable and effective during heating, sterilizing, and cooling phases.

Validated Depyrogenation & Sterilization

Dry Heat up to 280 °C: Validated for both sterilization and ≥3-log reduction of endotoxins.

Exceptional Uniformity: Ensures reliable and consistent processing of glassware and components.

High Load Capacity: Designed to support both small and large-scale pharmaceutical operations.

Technical Specifications

Cleanroom Classification: ISO 14644-1 Class 5 (Class 100) maintained throughout the cycle

Operating Temperature: Up to 280 °C continuous operation

Airflow Type: Unidirectional laminar airflow

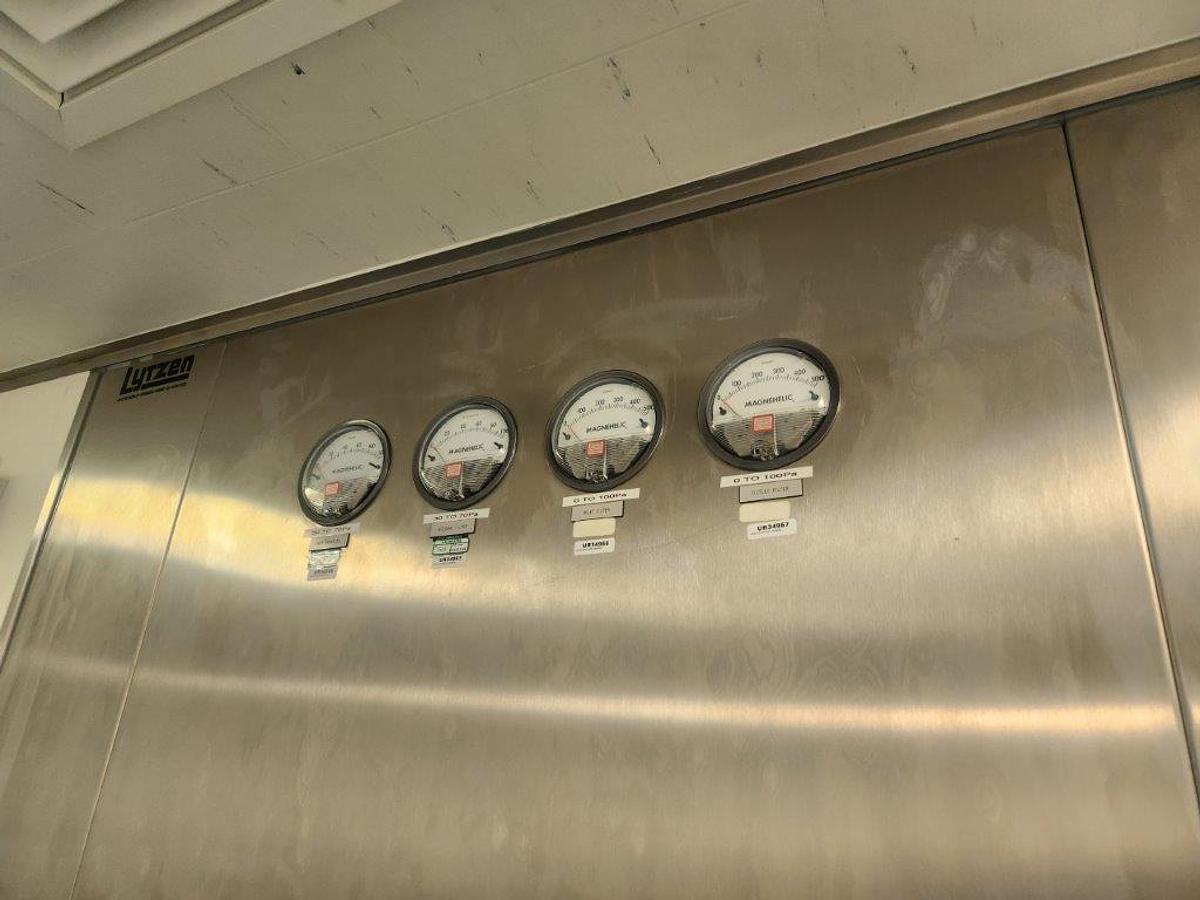

Filtration: HEPA H14 filters with advanced suspension system

Chamber Material: AISI 316L stainless steel interior

Controls: Siemens HMI interface

Validation: GMP-compliant; supports IQ/OQ/PQ and CFR 21 Part 11 compliance

Applications

Pharmaceutical: Vial, ampoule, and glassware depyrogenation

Biotech: Sterile preparation of components before aseptic fill

Sterile manufacturing: Endotoxin removal for GMP environments

Laboratory: Pilot-scale sterilization and dry heat validation

Benefits

True ISO Class 5 at 280 °C – unmatched cleanroom integrity during high-heat operation

Regulatory Confidence – supports global GMP and FDA requirements

Superior Engineering – long filter life and low maintenance through innovative construction

Process Consistency – validated, repeatable depyrogenation cycles

Scalable Solutions – available for lab, pilot, and full production use

Specifications

| Manufacturer | Lytzen |

| Model | ISO Class 5 (Class 100) |

| Condition | Used |

| Stock Number | 6073746 |